Abrasive materials can wreak havoc on conveying systems and Carbo Ceramics’ application is a perfect example. To read the full case study, click here.

The Eufaula, Ala.-based manufacturer was performing weekly repairs on the worn elbows of its ceramic bead plant. The company replaced all 12 elbows in their system with HammerTek® Smart Elbow® deflection elbow technology. The Smart Elbow units have lasted at least four years compared to the one- or two-week lifespan of their previous elbows. 892

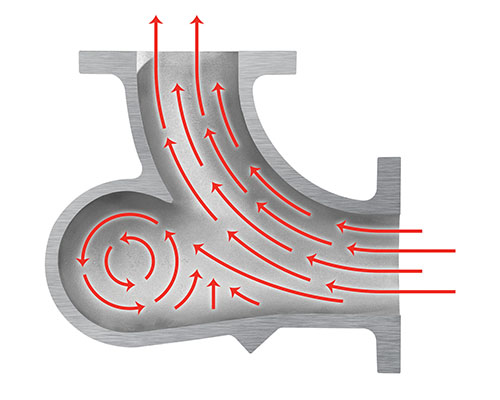

The cast aluminum line of Smart Elbow® deflection elbows from HammerTek® is now offered in tube and pipe sizes from 1.5 inch (3.8 cm) up to 12 inch (30.5 cm) in diameter. Suitable for dilute-phase and dense-phase pneumatic conveying systems, the deflection elbows eliminate problems associated with material impacting conventional elbows at high speed including: abrasive wear, breakage of friable materials, plugging of heat-sensitive materials and generation of fines, plastic streamers, snake skins and angel hair.

The elbows feature a spherical chamber that protrudes partially beyond the desired 90° or 45° pathway, which causes a ball of material suspended in air to rotate, gently deflecting incoming material around the bend without impacting the elbow wall or generating heat. 785

Even innocent-looking PET poly pellets can wreak havoc on conveying systems when the perfect storm of variables come into play. Such was the case with Schmalbach-Lubeca’s Blythewood, SC plant. Manufacturing plastic bottles for use in the beverage industry is a 24/7 operation, and line shutdowns were proving to be an expensive problem.

Similar to many manufacturing and production facilities, the Blythewood plant used conventional long-sweep elbows as part of the conveying system, moving the pellets from storage silos to molding machines. The problem? The way conventional elbows function. The design of a conventional elbow changes the direction of conveyed material through deflection off the inner walls, causing friction and heat.

You can read the full case study here.

876

To comply to federal sulfur dioxide emissions standards, PECO Energy Company’s Eddystone plant employs a scrubbing process using magnesium oxide (MgO). The material is pneumatically conveyed from storage silos to a mixer before being sprayed into the exhaust stacks. Producing electricity is a 24/7/365 operation and the MgO system must always be running. Simply put, elbow failure is not an option.

In reality, however, the standard 316L stainless pipe elbows that made up the pneumatic conveying system were wearing out at an average of every four to six months, resulting in environmentally hazardous and costly spillages. Annual labor costs related to cleanup and repairs soared. 705

Montgomery County’s North Incinerator plant outside Dayton, Ohio, uses finely powdered limestone in its three incinerator units to bring sulfur dioxide emissions (a by-product of combustion) in line with EPA air pollution standards.

Each day, approximately 18,000 pounds of the highly abrasive, dusty material are conveyed through the facility using long-radius stainless steel sweep elbows. Long considered the industry standard, these conventional sweep elbows are critical components in any conveying system. Failures at these crucial points can be costly, messy affairs that negatively impact productivity. The powdered limestone was quite literally wearing the sweep elbows away from the inside out.

Moving such a high volume of material non-stop requires high pressure. If even a small leak develops in a sweep elbow (and they occurred frequently), the result would be a huge cloud of dust as the powdered limestone spewed out under pressure. A breach required immediate shutdown of the lines for repair and cleanup — and the clock started ticking: EPA regulations require a complete (and expensive) incinerator shutdown if the line shutdown lasts more than a few hours.

You can read the full case study here.

611

Breweries like Miller Brewing Company’s Fort Worth, Texas facility demand efficient use of space — and for good reason. The production of beer from grain to glass requires moving barley malt and water (the two primary ingredients) from storage vessel to mash tun to boil kettle to bright tank.

Plagued by maintenance and housekeeping problems stemming from a single automatic diverter in the grain upload system, Roy Marin, staff engineer at the facility, decided to replace the troublesome component with a more cost-effective piping panel. The original design specifications included a manifold with a dozen 4-foot radius sweep elbows, but therein laid the problem: there wasn’t enough room at the installation point. 607

When you’re in the business of manufacturing and handling abrasive materials, line plugs and worn-out elbows (and the resultant downtime and losses in productivity) are troublesome and costly realities.

That was exactly the case for Dave Goodwin, Plant Maintenance Superintendent for the Scarborough, Ontario plant of Fiberglas Canada. Goodwin’s plant suffered through as many as 20 wear-related clogs per year — always occurring at the same two refractory elbows in the conveying system connecting the batch house and the furnace hall.

604

Even the most seemingly innocuous materials can be become destructively abrasive when moved pneumatically — maintenance manager Al Husni of ACRO Extrusion Corporation saw it firsthand. A Wilmington-based company, ACRO produces vinyl window systems and extrusion. PVC resin, a key component in vinyl formulations, was moved pneumatically at such a high rate (34,000 pounds per day), traditional sweep elbows were wearing through as often as every 14-21 days.

These line failures were costly. Repairs and cleanups consumed valuable man-hours, and any leaked material potentially subjected the company to EPA fines. 601

February 25, 2016

Abrasive Cement Dust No Match for the Smart Elbow® Deflection Elbow

Essroc Materials Inc. produces nearly 400,000 tons of cement annually using two 400-foot rotary kilns. The wet-process cement in Frederick, Md. was continually plagued by dust produced as a natural by-product of cement kilning.

How much dust? Try 120 tons of dust every 24 hours.

A portion of this dust is sold for use in various industrial and agricultural applications, but the majority must be moved pneumatically and recycled back through the kilns through a process call insufflation.

And that’s where the problems really begin.

595

February 9, 2016

Smart Elbow® Deflection Elbow Make Wise Investment

With a daily volume exceeding 80 million gallons of water treated, the Alexandria Sanitation Authority knows a little bit about the need for efficiency and just how catastrophic line breaches can be. To control pH, the facility uses more than 500,000 pounds of pelletized lime each month. Trucks deliver the material to 70-foot silos via a pair of four-inch lines.

Due to its abrasive nature, pelletized lime was wreaking havoc on the conveying system by literally wearing the traditional long-sweep elbows from the inside out. The never-ending cycle of repair-and-replace began within six months of elbow installation.

593

Hammertek’s Smart Elbow® deflection elbow saves space, time and money. If you’ve ever read this blog, you know that. Practically every article we’ve posted has highlighted the tangible benefits realized by companies across multiple industries once they’ve made the switch to Smart Elbow products.

The combination of a small footprint and innovative design make the Smart Elbow deflection elbow an ideal solution for high-wear, high-volume environments. 589

PECO Energy Company’s Eddystone plant employs a scrubbing process using magnesium oxide (MgO) pneumatically conveyed from storage silos to a mixer before being sprayed into the plant’s exhaust stacks — a process necessary to keep the plant in compliance with federal sulfur dioxide emissions standards. Whenever the coal-fired plant is generating electricity, the MgO system must be operational. Elbow failure is not an option.

585

December 8, 2015

HammerTek solution eliminates toughest obstructions

Many manufacturers of abrasive materials fight a losing battle in their conveying systems. The root cause of constant pipeline problems along the entire manufacturing process is the abrasive material being conveyed, wearing through conventional sweep elbows at an alarming rate.

Chromalloy’s Drilling Division was experiencing problems every 90 days. The companys Houston plant produces ground barite (barium sulfate), an abrasive compound used in commercial drilling operations. The high-density material was wearing through 4- and 5-inch pipe elbows in the pneumatic system that transported the finished material from the grinding mills to storage tanks. 546

November 16, 2015

Smart Elbow® deflection elbow virtually eliminates wear

Fiberglass is an especially abrasive material. RheTech Inc.’s long-sweep elbows were being worn away little by little until the inevitable happened — an expensive breech in the conveying system. The result was costly: product spillage, line shutdowns, and a substantial impact on productivity.

Gary Wright, RheTech’s director of Plant Engineering, was convinced there was a more efficient and cost-effective way to keep the conveying systems operational. 575

October 26, 2015

Smart Elbow® deflection elbow solve space issues too

Commercial breweries operate under some extremely tight quarters. Storage vessels for raw ingredients (especially malted barley), fermenters, bright tanks and chillers occupy large footprints on the production floor. Facilities managers are continually seeking out ways to increase production yields and efficiencies without losing square footage for the people operating and maintaining equipment.

When the grain upload system at Miller Brewing Co.’s Fort Worth, Texas plant needed a complete redesign and equipment upgrade, staff engineer Roy Marin saw an opportunity to eliminate the troublesome automatic diverter, which plugged regularly, with a more cost-effective and efficient solution. 572

October 15, 2015

Smart Elbow® deflection elbow eliminates blowouts

When wastewater treatment plants experience blowouts, cleanup is costly. Of course, there’s the cost of labor and materials, but there’s also potential fines as well as the obvious health risk and safety concerns.

The Upper Occoquan Sewage Authority (UOSA) wastewater treatment plant in Centreville, VA, handles nearly 30 million gallons per day to provide potable water to more than 300,000 residents in northern Virginia. In order to raise the pH of the water to levels optimal for the efficient removal of bacteria and phosphorus, the chemical treatment system uses pebble lime. This material is conveyed non-stop 24 hours per day, 365 days per year — unless the system malfunctions. 569

September 16, 2015

Innovative thinkers behind our success stories

Regular readers of this blog know that in case after case, HammerTek’s Smart Elbow® deflection elbows have eliminated wear-related leaks in pneumatic, liquid, slurry and steam conveying lines across multiple industries. When manufacturers install Smart Elbow products to address line failures, they see benefits almost immediately – less line down time, drastically reduced maintenance and cleanup costs, and significantly increased productivity.

By eliminating leaks of EPA-regulated materials common in many manufacturing processes, Smart Elbow deflection elbows further eliminate costly fines associated with the spillages. 564

September 2, 2015

Smart Elbow® deflection elbow outlasts even silica aggregate

Silica aggregate, a key component in industrial flooring products produced by Stonhard Inc, at its Ft. Wayne, IN plant is an incredibly coarse and abrasive material — and the company was seeing first-hand how mercilessly it was wearing down components in its pneumatic conveying lines.

According to Greg Sosenheimer, plant manager, 82,000 pounds of the material moves through the system each day, and the ceramic elbows Stonhard used to direct and funnel the flow of silica aggregate from blending vessels to holding silos just couldn’t hold up to the high-wear conditions. In fact, elbows were failing on average every three months, and replacement costs and productivity losses were rising to unacceptable levels. 562

Rennselaer Plastics Company produces PVC piping products for the plumbing trade, utilizing a pneumatic conveying system to move plastic resin beads and pellets from outdoor storage hoppers to its pipe extruders.

Each part of the manufacturing process operates under strict controls, the machinery tuned precisely and using the latest technology.

Despite all the protocols, L.E. Koehler, assistant plant manager, had a persistent headache on his hands: the abrasive nature of the plastic resin was rapidly wearing away the long-radius sweep elbows commonly used in pneumatic conveying systems. Koehler’s team was replacing the elbows every two to four months on average. Maintenance and downtime costs were chewing away at the company’s profits as quickly as the resin was chewing away at the elbows. 559

When you’re in the business of manufacturing and handling abrasive materials, downtime and expense caused by line plugging and rapidly wearing elbows are almost inevitable.

That’s what Dave Goodwin, Plant Maintenance Superintendent for the Scarborough, Ontario plant of Fiberglas Canada, believed. Goodwin’s plant suffered through as many as 20 wear-related clogs per year — always occurring at the same two refractory elbows in the conveying system connecting the batch house and the furnace hall. 552